Foundry

Specializing in Aluminum and Bronze foundry, Socométa produces small to medium series parts weighing up to 200 kg using its gravity or low-pressure casting process.

The parts can be produced with cores or metal inserts, and we also offer heat treatment services.

Foundry

Specializing in Aluminum and Bronze foundry, Socométa produces small to medium series parts weighing up to 200 kg using its gravity or low-pressure casting process.

The parts can be produced with cores or metal inserts, and we also offer heat treatment services.

Our alloys: Al Si 12 - Al Si 10 Mg - Al Si 7 Mg - Al Si 7 Mg 0.6

Aluminum Foundry Shell moulding machines

Socométa produces individual or series parts, from the simplest to the most complex, in aluminum. Experienced teams master the casting process, whether manual or assisted gravity.

Each autonomous unit ensures excellent casting responsiveness and perfectly controlled quality. Machines with automation manage solidification times, and air or water cooling systems guarantee the metallurgical qualities of the parts.

Low-Pressure Aluminum Foundry

The low-pressure aluminum foundry process is particularly suitable for large-sized parts. These parts can measure up to 1 m³ and weigh 200 kg.

The low-pressure aluminium die casting process offers an ideal solution for large parts. Low-pressure die casting involves vertically injecting liquid aluminium from a furnace placed under the mould via a tube. The molten aluminium is pushed upwards by a neutral gas whose pressure is slightly higher than atmospheric pressure, forcing it to rise up the tube and fill the mould cavity. This process enables a higher level of quality to be achieved, as well as the manufacture of large parts with complex geometries.

Like the shell moulding machines, low-pressure equipment is equipped with automation to control part solidification and air or water cooling circuits.

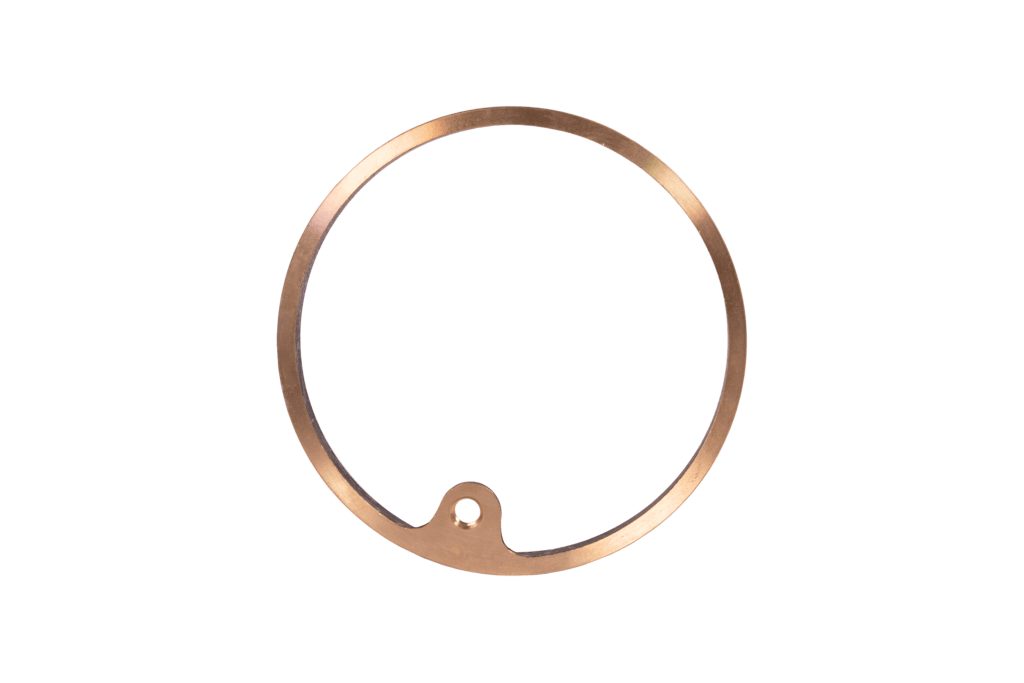

Our alloy: CuSnx

Bronze Foundry

Socométa has a dedicated production unit for manufacturing bronze and copper-aluminum castings using the shell method.

The metal, drawn from a regulated furnace, is poured into a metal mold coupled with an automatic machine called a “shell machine.”

This technology is well-suited for producing parts, with or without steel or cast iron inserts, weighing from a few grams to 10 kg and having a maximum diameter of 400 mm.

Our traditional island-based organization offers similar advantages to our aluminum foundry, ensuring efficient and controlled production processes.

Our Strengths

3D Printing

Thanks to our privileged partner, Socométa utilizes additive manufacturing technology, enabling the rapid design of foundry parts without the need for tooling through 3D printing of the mold. This process is particularly useful for prototypes or small production runs.

Core making

Coring equipment complements our foundry equipment, allowing us to create complex shapes. We can also utilize the 3D sand printing process for core manufacturing.

Heat Treatment

Socométa has a heat treatment furnace. For certain alloys, heat treatment enhances mechanical properties, providing improved tensile strength and greater hardness.