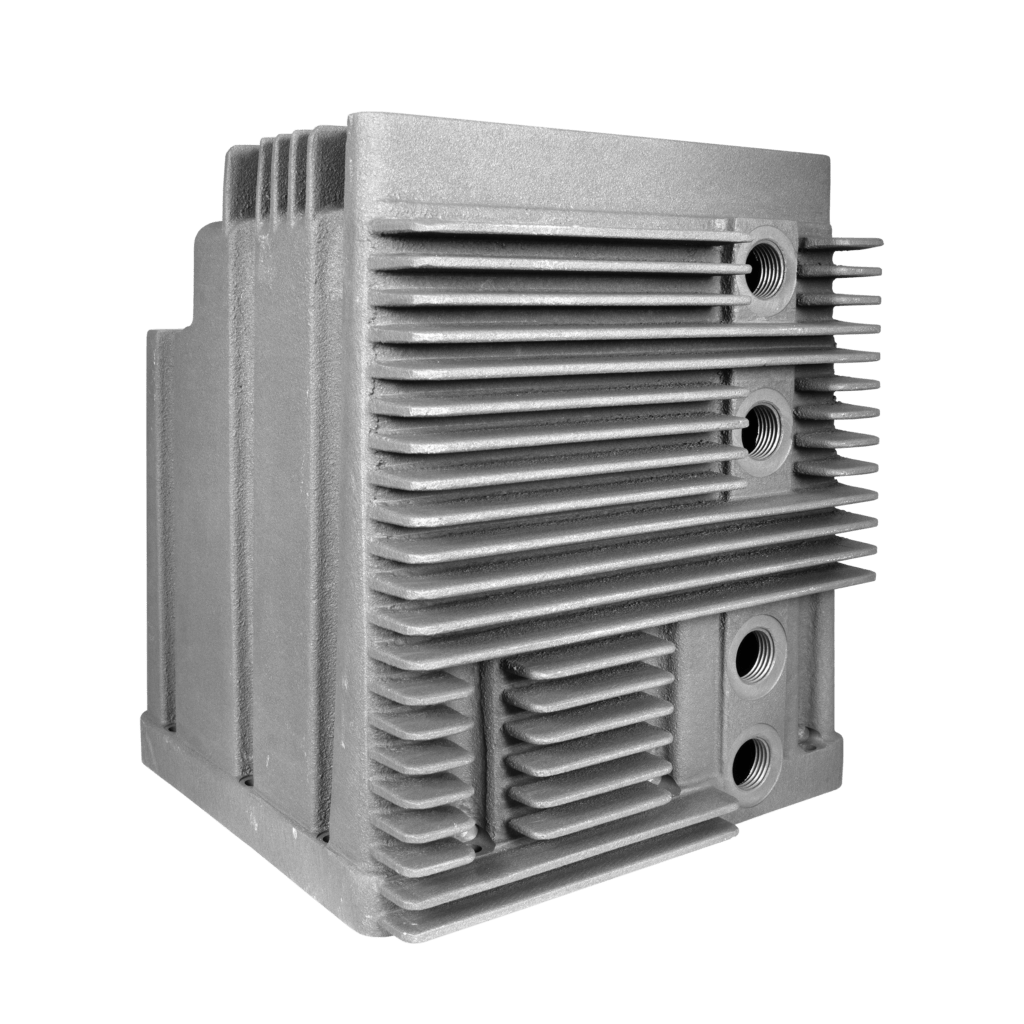

Quality and Control

Socométa places a high emphasis on quality, focusing on precision and control throughout the various stages of the process.

Our diverse control methods ensure that your parts conform to your drawings, specifications, and requirements. Upon request, we can provide you with certificates of conformity.

Quality and Control

Socométa places a high emphasis on quality, focusing on precision and control throughout the various stages of the process.

Our diverse control methods ensure that your parts conform to your drawings, specifications, and requirements. Upon request, we can provide you with certificates of conformity.

Socométa's Controls

Material Composition by Spectrometer

Validates the quality of aluminum, bronze, or copper alloys.

Durometer Control

Ensures the perfect execution of heat treatment.

Helium Leak Testing

Certifies the airtightness of parts.

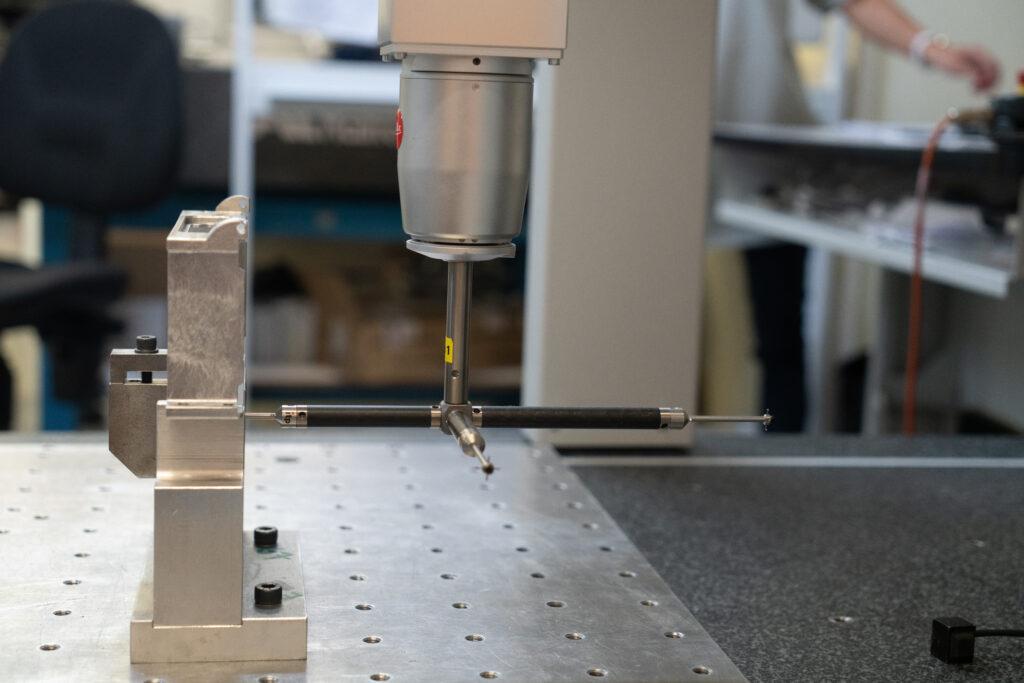

Dimensional Control by Scanning

Measures complex shapes in relation to the 3D file or for reverse engineering.

Tomography Control

Ensures the integrity of the material.

Three-Dimensional Inspection

Measures machining precision.